Abstract:

Production management is concerned with the creation of products and services using a business model. They’re also relevant in service and manufacturing businesses. The application of management and concepts to the production function in a factory is referred to as production management.

Production management, in basic terms, entails the planning, coordinating, directing, and controlling of the manufacturing process. It holds a critical position at the heart of an enterprise, balancing the need to deliver value to the business (typically profit) with what consumers want and what’s technically and operationally feasible. This article aims to elaborate importance and functions of production management.

Table of Contents

Aim of Production Function in Production Management –

The production function’s aim is to add value. If it’s a product or a service, the goal is to create something that strengthens the organization’s relationship with its customers. This, however, cannot be accomplished solely by the production department.

The marketing department has a significant role to play in this. They would be the ones to distribute the goods to potential clients, and they should be able to tell the manufacturing department what customers or consumers want.

Production Management has a wide range of responsibilities. However, the sole goal is to ensure that the company delivers high-quality goods that meet the needs of consumers on a consistent basis.

Functions of Production Management –

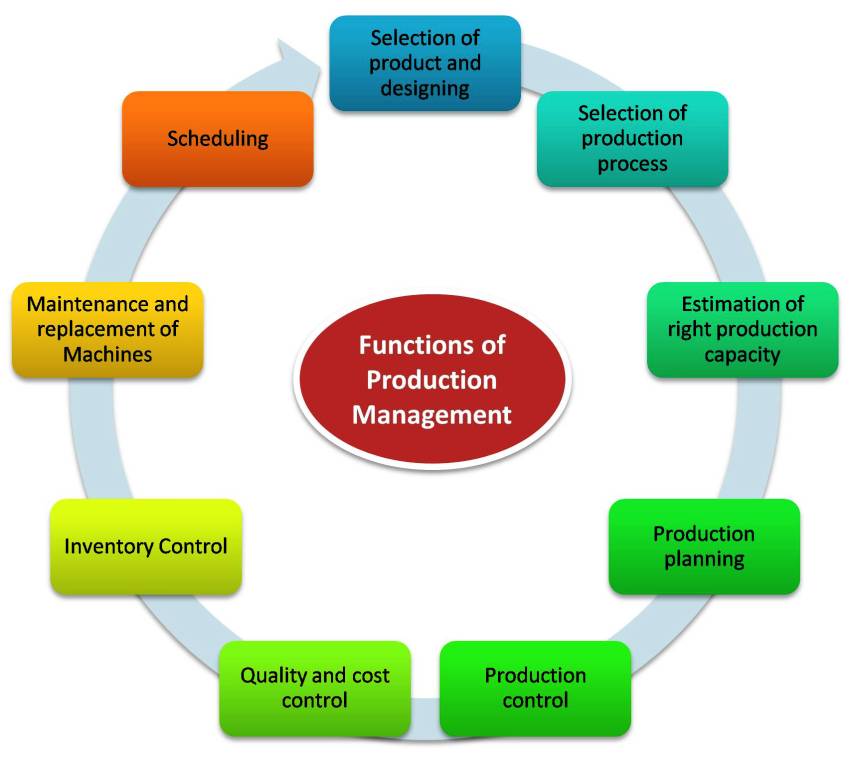

Production Management entails the following functional components —

- Selection of product and designing

- Selection of production process

- Estimation of right production capacity

- Production planning

- Production control

- Quality and cost control

- Inventory Control

- Maintenance and replacement of Machines

- Scheduling

1. Selection of Product and Design —

Selection of product and designing of the same plays a pivotal role in a business venture. It is imperative for the company to approach the market with economical and valuable products from time to time which shall ensure the success and progress of the company.

A product that is to be produced by the company must be selected and designed using value engineering and value analysis. The product should be selected only after overall evaluation and assessment, after selection of the product the selection of the design must follow.

2. Selection of Production Process —

The production process should be planned way before it actually starts. After the selection of product is done and the design has been decided, thereafter comes the selection of the production process. It is one of the important function of production management.

The right production system must be selected, the man power required to produce the same shall be estimated and recruited, the type of technology that shall be used, the amount of capital that shall be required must be decided. The machines that would be put into work, the engineering, the material handling system, all shall be selected and prepared for a smooth and successful work function.

3. Estimation of Right Production Capacity —

The selection of the right production capacity plays a huge role in production management. For this, the right demand for the product shall be estimated, and then it must match with the production capacity.

A wrongful estimation may affect the production of the product, as less or more capacity than actually needed might create problems. The break-even analysis for planning the production capacity may prove to be significant. The production management team must be prepared with a planned layout for both long term and short term production.

4. Production Planning —

One major function in production management is to plan the production process. The production management hereby must decide on the routing and scheduling.

Routing basically decides for the path of the production process, the sequential operation that shall take place, whereas scheduling being the means to plan the whole production process, as to when it shall be started, and when the production activity shall come to an end.

5. Production Control —

Controlling the production process is the next job of paramount importance, that the production manager shall handle. The production planning and the actual process shall be tallied and if any deviations from the actual planning are found, that must be met with necessary steps for its correction.

6. Quality and Cost Control —

Quality and cost control plays a huge role in the company’s upliftment, the buyers want the products to be of top-notch quality at fair and low prices. The production manager thus has to try to maintain the quality of the product and should try to lower the production cost, as it shall in turn lower the cost of the product.

7. Inventory Control —

Inventory control is also part of production management. The inventory level must be monitored by the production manager. Overstocking and understocking of inventories are not appropriate.

If there is an overabundance of materials, the working capital will be stifled, and the materials can spoil, be wasted, or be misused. If there is a shortage of inventory, manufacturing will be delayed, and deliveries will be disrupted. Thus, the production manager shall effectively control the inventories.

8. Maintenance and replacement of Machines —

The production management ensures that machinery and equipment are properly maintained and replaced. All the machinery that would be needed for the production shall be checked prior to the actual production process.

The production manager must have a system in place for regular inspections, oiling, washing, replacement, and repair of machines, machinery, and spare parts, among other things. This helps to stop unforeseen technical breakdowns and production halts.

9. Scheduling —

When it comes to taking a manufacturing process to the next stage, production scheduling is crucial. The allocation of raw materials, labour, and processes to manufacture goods for customers is known as the production schedule.

The objective of production scheduling is to make the manufacturing process run as smoothly as possible by matching the production requirements with the available resources in the most cost-effective way possible.

Solid management combined with the right production planning and scheduling technique is needed for the best production. Even the simplest business can be turned around without a solid plan to handle and schedule production.

Significance of Production Management –

Production management aids the company in achieving all of its goals. It creates goods that cater to consumers’ expectations and desires. As a result, the company’s revenues will rise.

This will assist it in achieving its goals. Production management aids in the company’s customer satisfaction. It improves a company’s credibility, goodwill, and image. A positive image aids the company’s expansion and growth. The introduction of new goods to the market is supported by production management.

Production management works as a research & development team for the company. This enables the company to develop innovative, higher-quality products at lower prices. These products are popular in the market because they provide full customer satisfaction.

Conclusion —

Production Management in the simplest meaning is the backbone of a company’s overall development. The other major functional areas of an enterprise, such as marketing, finance, and staff, are efficiently supported by production management.

The marketing department will have an easier time selling high-quality goods, and the financial sector will receive more funding as a result of the increased profits. For expansion and modernization, it will receive more loans and equity capital. The personnel department can efficiently handle human resources thanks to the manufacturing sector’s excellent results.